In a recent article published by the BBC, Ofgem predicted household energy bills would more than double over the next year. Naturally, we’re conscious of how this stark increase will translate to businesses, and how the rise in costs of resources and operations will impact our sector.

But with a little innovative thinking around energy consumption, there are ways in which you can reduce the associated costs. Whether utilising formulations that require cold processing or adding ingredients that reduce production time and overall manufacturing costs, or developing formulations that are quick rinsing to help the end consumer, there are a range of energy-saving solutions available.

At Cornelius we are constantly thinking of ways to reduce energy usage across the board and we believe it is important to buffer the impact of climbing energy costs as much as possible, with the solutions we know we have access to. Take a look below at our list of sustainable solutions; unique cosmetic ingredients that can contribute to reducing your energy expenditure in your manufacturing processes.

Cor-Sil Avance™

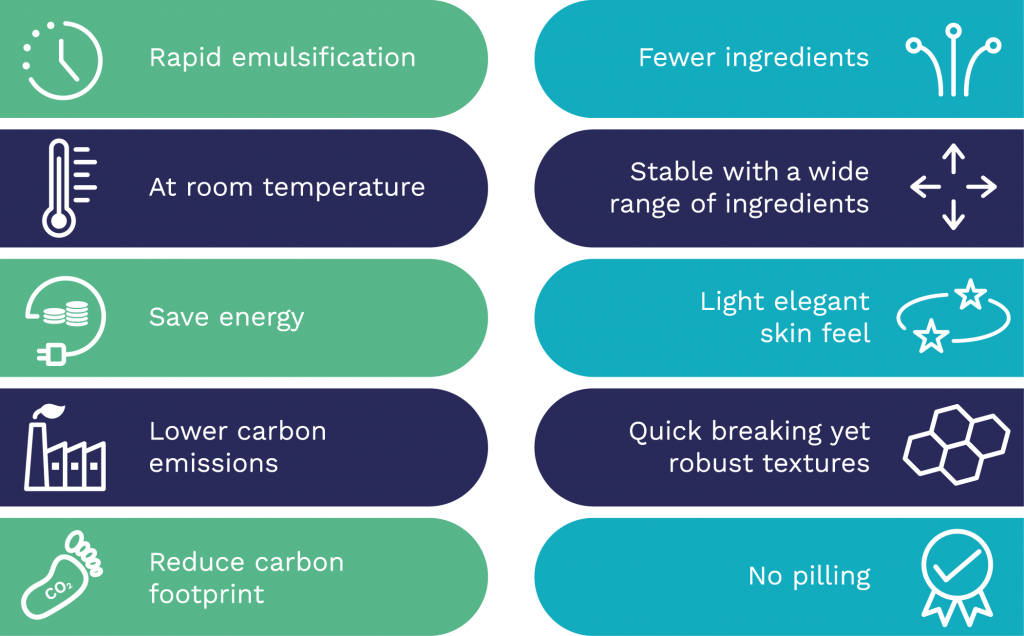

Cor-Sil Avance™ has a unique molecular structure that delivers multiple energy saving benefits, developed by our innovation & technology team, together with our very own Ella Ceraulo. Cor-Sil Avance™ gives the benefit of rapid emulsification, which can reduce lab and factory production time by up to 50%. This ability to emulsify at room temperature means that it reduces the heating process by up to 50°C. The scale-up process of Cor-Sil Avance™ from lab to factory is up to five time more efficient than a traditional process.

Jeesperse®

The Jeesperse® range is a unique cold mix technology created and patented by Jeen. The extensive range combines traditional, specialty, and natural waxes with a variety of emulsifying ingredients, meeting a range of formulating requirements.

The technology is built on the interaction of generally non-polar waxes with polar, emulsifying electrolytes. These are combined into optimised powders that, when introduced into water at room temperatures, rapidly form stable emulsions, thus eliminating the need for traditional emulsifiers and allowing the addition of waxes into the system without heating. Key benefits of cold processing include energy cost savings, reduction in water usage and overall manufacturing production time savings.

Gelest Hydrosperse

Gelest Hydrosperse Iron Oxides have a unique surface modification. This anionic, hydrophilic reacted coating enables the pigments to disperse instantly in aqueous media without high shear agitation. Simplistic dispersion improves batch conformity as well as reducing time and energy costs as, unlike regular iron oxides, milling is not required for these specialised grades.

SNF Gelling Agents

SNF have a wide range of gelling agents across four different product families:

Flocare™ C: Liquid polyquaterniums that bring lubricity and softness to hair and skin.

Flocare™ SK: A powder polymer which creates a soft feeling crystal clear gel, without the need for neutralisation.

Flocare™ Inverse Emulsions: Available in liquid and dry form, these create immediate emulsions with minimal agitation, and again no neutralisation required.

Flocare™ DE: A thickener and suspending agent for wash products which results in clear formulations.

All of these materials are cold processable, reducing energy output and associated costs.

Strahl & Pitsch

A number of blended materials are available from Strahl & Pitsch which nullifies the need to purchase multiple materials, and reduces the energy required to combine these elements.

Two lip balm bases are available – these blends of natural oils and waxes are available in two versions, one for sticks, and another for tube balms. Natural wax jelly is an alternative to petrolatum and comes in several grades, including a vegan version all of which are a blend of natural materials.