Core Products

At Cornelius UK Manufacturing, we are at the forefront of chemical innovation, specialising in the production of a diverse range of high-quality chemical compounds tailored to meet the exacting standards of the ocular and medical industries. Renowned and trusted by industry specialists, our advanced facilities excel in both monomer and polymer production. Our commitment to precision, quality control, and sustainability sets us apart.

We excel in delivering materials that exceed expectations. With capabilities ranging from distillation to reprocessing, we offer flexibility and customisation to match specific application needs. Take a look at some of the exceptional materials we produce and learn more about the expertise that drives our progress and success across multiple sectors.

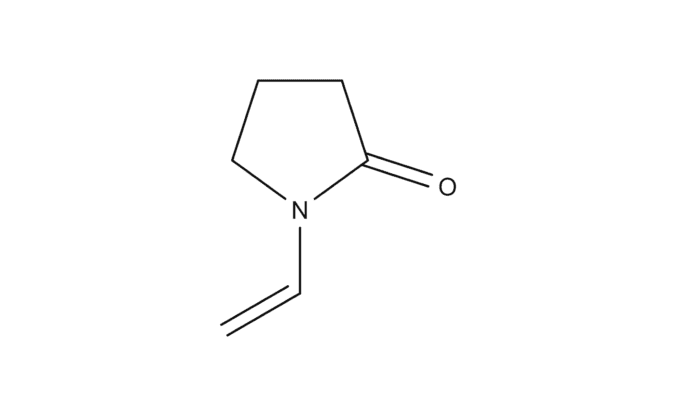

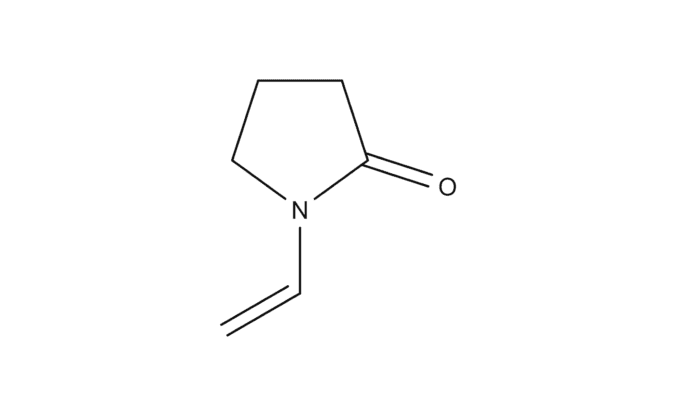

NVP

N-Vinyl-2-pyrrolidone (NVP) exhibits valuable qualities in both contact lens manufacture and medical applications.

In contact lens production, NVP polymerises to form polyvinylpyrrolidone (PVP), which imparts hydrophilic properties to lenses, ensuring moisture retention and enhanced comfort.

In medical applications, PVP’s biocompatibility is harnessed for wound closure and tissue sealants, providing a less invasive alternative to sutures.

NVP’s adaptability in forming biocompatible materials makes it a versatile and beneficial component in both industries.

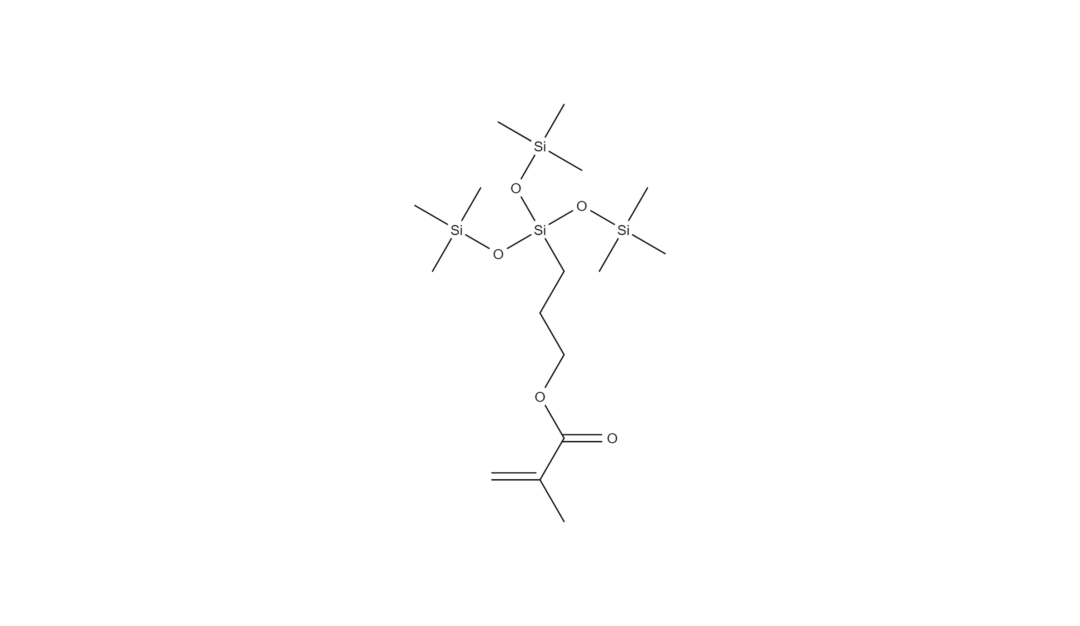

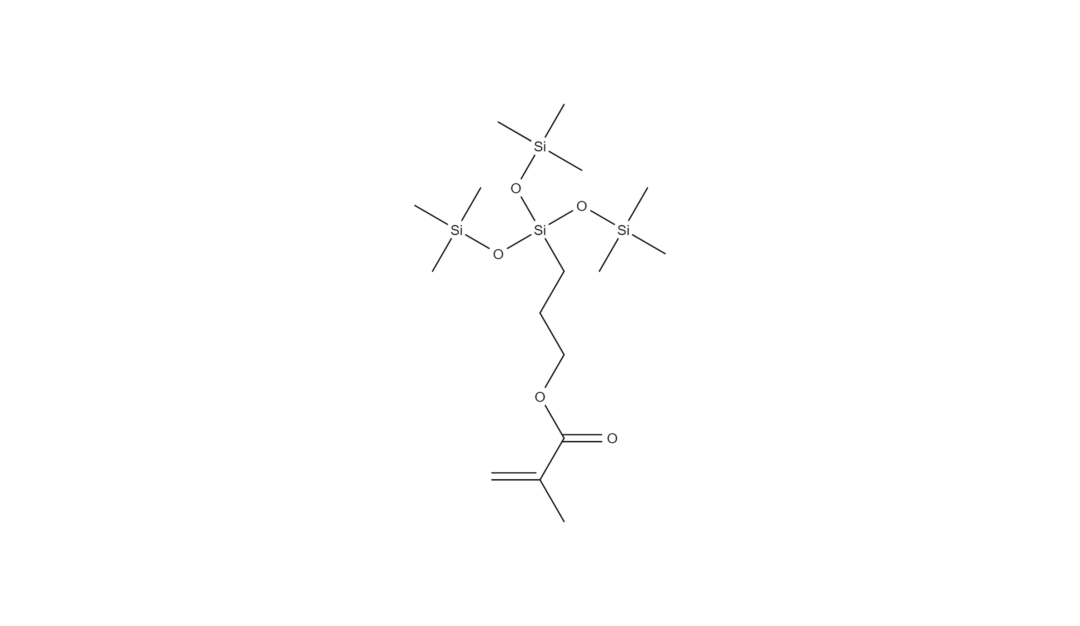

3MPMS (0Ultra)

(3-Methacryloyloxypropyl)tris(trimethylsiloxy)silane exhibits advantageous qualities in both contact lens manufacturing and medical applications.

Its methacryloyloxypropyl functional group facilitates polymerisation, contributing to the formation of durable and biocompatible contact lenses with improved mechanical properties. Additionally, the trimethylsiloxy groups enhance the compound’s compatibility with silicone-based materials, making it suitable for advanced contact lens designs.

In medical applications, 3MPMS plays a role in formulating adhesives with superior bonding capabilities. Its silane functionality enables effective adhesion to diverse substrates, providing a reliable and long-lasting bonding solution in medical applications, such as wound closures and tissue sealants.

Overall, the compound’s dual functionality makes it a valuable component in enhancing the performance, durability, and biocompatibility of both contact lenses and medical adhesives.

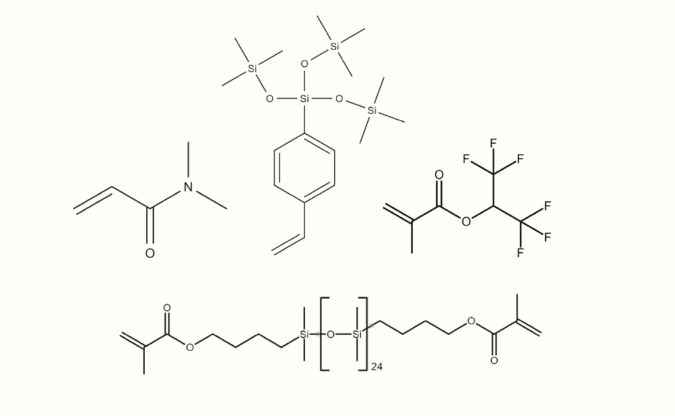

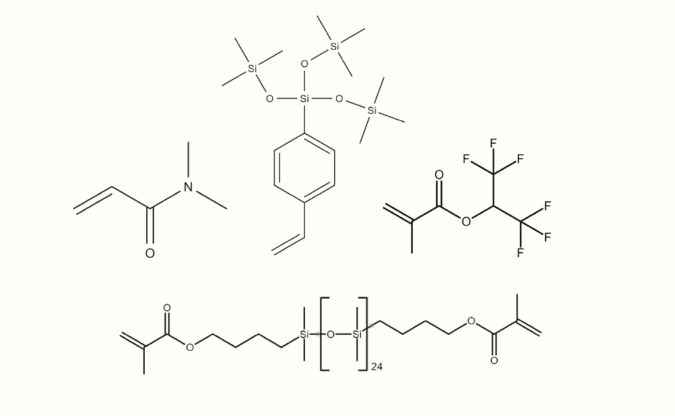

Full Range

We are also well versed in the production of other applications at our UK Manufacturing site. These are again suitable for ocular and medical applications, however are not restricted to these alone.

Other materials:

TTMS (Tris (Trimethylsiloxy)silyl styrene)

BMB- PDMS 25 (bis-methacryloxybutyl polydimethylsiloxane)

DMAA (N,N-Dimethylacrylamide)

HFPMA (1,1,1,3,3,3-Hexafluoropropyl Methacrylate)

For further details on these materials, please don’t hesitate to reach out to us using the contact form below.

Process Support

Our chemical manufacturing processes are fortified by a dedicated team of professionals, including an Innovation & Technology department, which serves as the backbone of our chemistry endeavours. This dynamic team plays a pivotal role in supporting various facets, from process improvements to assisting with scaling up our capacity, and resolving technical challenges.

Complementing their efforts is our Engineering department, ensuring the reliability of our operations by maintaining and readying all equipment and plant facilities for use. This department not only guarantees the optimal functioning of our machinery but also actively contributes to process enhancements and the expansion of our production capabilities.

Together, these collaborative efforts reflect our commitment to continued improvement, underpinning the success and reliability of our chemical manufacturing processes.